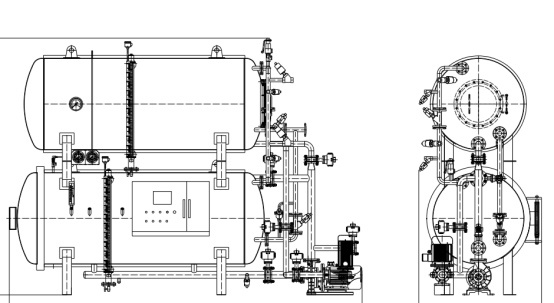

Immersion Retort

- Product description

-

Production instruction:

Water Immersion sterilization pot, hot water tank and sterilization process tank volume is equal, sterilization effect is strong penetration, rapid heating and rapid cooling, sterilization without dead Angle, to achieve sterilization state has little impact on the product.

The Water Immersion Process is the most widely accepted method of sterilizing products using an over-pressure process. The Water Immersion process totally isolated from any influence of cooling air. The product is totally submerged in water. It is different from Saturated Steam in that air can be introduced into the vessel during sterilization. Overpressure is provided by introducing air (or steam) on top of the water. In some instances, the air is added to the steam (which then heats the air). The heated air agitates the water as it flows to the surface and serves to pressurize the processing load.

Shenlong machinery water Immersion sterilization pot, Firstly water saving and energy saving, low production cost. Secondly,high steam utilization rate, low noise. Thirdly,safe and reliable manpower, sterilization pot choose Shenlong, Give you peace of mind.

Advantage:

- Four safety interlocks and a quick door opening device.

- Easy to operate and install, we can achieve online guidance and one touch start.

- The quality is stable, using selected materials and high-quality spare parts, making it durable.

- The up and bottom diameter and length of the tank are the same size. Upper tank is storage hot water tank, which can quickly fill the bottom tank during sterilization, and the product heats up quickly. After sterilization, the sterilized water can be recycled to the upper tank, saving water resources and steam heat energy. The insulation materials are polyurethane and glass wool.

- The hot water flow circulation achieves the best heat distribution in the sterilization retort and ensures the uniform sterilization effect of the product.

- The product is completely immersed in sterilizing water and does not come into contact with the air. There is no air cold mass in retort chamber, and the temperature penetrates into the product in all directions, resulting in high sterilization efficiency.

Application:

- Flexible package:Flexible retort pouches, Aluminum foil bages, Retort bages, Vacuum bags

- Soft / Large package

- Color/shape sensitive products, such as sweet corn.

Product Packaging

Waterproof paper, and steel strip packed. Standard Export Seaworthy Package.

Shipping Method

Shipping by containers / Shipping by bulk ship

Customized Services

Packaging and transportation methods can be customized according to customer requirements.

Tag list

TESTING EQUIPMENT

Delivery site

Delivery site

Delivery site

Delivery site

Delivery site

Delivery site

RECOMMENDED

All-round spraying and Gentle cooling: Choose spray retort for Indirect Linear cooling.

Complete heating and non-solidification:Choose Rotary Retort for Stratification and sedimentation food.